Bypass-type flow measurement technology

Publish Time:

2020-03-26 17:57

Source:

1. Shunt

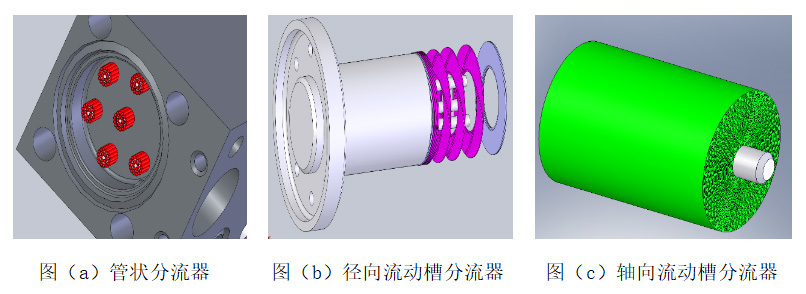

Shunts mainly include annular channel, tubular channel, slot channel, and mesh channel shunts.

The function of a shunt is to provide the sensor with a certain range of gas flow, regardless of the total flow rate of the flow meter. If the gas supplied to the sensor is too little, the sensor's signal output will be too weak. Although it can be amplified, noise will also be amplified simultaneously, preventing the flow meter from working. If the gas supplied to the sensor is too much, the sensor will operate in a non-linear region and may even cause the sensor's output to exceed its limit, leading to unstable operation. Therefore, the calculation of the shunt aperture and the determination of its quantity are crucial.

Figure 1 Shunts of different shapes

2. Application of Shunt Technology in Mass Flow Controllers

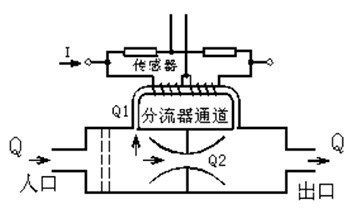

Gas Q enters the shunt channel of the mass flow controller from the inlet. Under the action of the shunt, the gas flow is divided into two paths: one path of gas passes directly through the shunt Q2; the other path passes through the capillary tube of the flow sensor Q1. Then, the two paths converge and flow out from the outlet. The flow sensor of the mass flow controller measures the gas flow passing through the capillary tube, and the obtained flow signal is sent to an amplifier for amplification.

Figure 2 Shunt working principle diagram

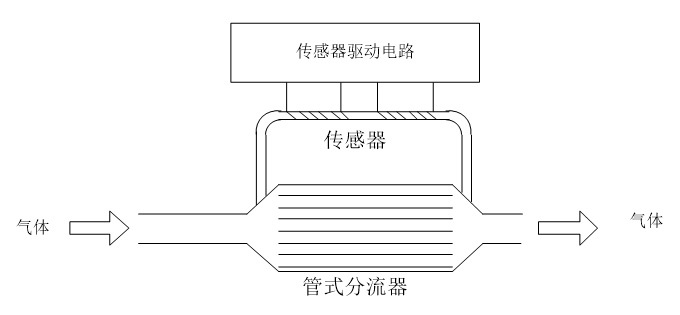

Figure 3 Schematic diagram of a tubular shunt

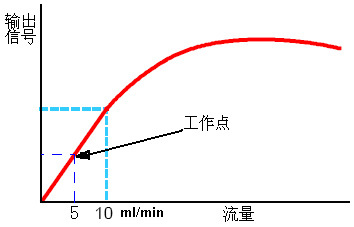

When gas Q gradually increases from zero, the output signal of the sensor also gradually increases from zero. This establishes a correspondence between a gas flow value and an output signal value, allowing for a relationship graph between the output signal value and flow, as shown in Figure 4.

Figure 4

The design of the shunt must not only ensure that it provides an appropriate flow rate to the sensor but also requires that the gas volume it provides is linear, meaning that for a certain flow range of the shunt, the shunting ratio should not change with the flow rate.

3. Advantages of Using Shunts

In practical applications, with the flow sensor unchanged, various flow specifications of gas mass flow controllers can be achieved by changing the shunt. Flow specifications range from 5 ml/min to 30L/min, with each flow specification corresponding to a specific shunt. Since the inner diameter and length of the flow sensor's capillary tube are known, by determining the length L and inner diameter d of the shunt tube, the required number of shunt tubes can be calculated. This precise calculation method yields the shunt calculation results, providing a theoretical basis and guarantee for improving product accuracy.

At the same time, using a shunt in the pipeline ensures that the gas in the mass flow controller is in a laminar flow state, providing stable gas environmental conditions for gas measurement within the sensor's capillary tube, thereby improving the measurement and control accuracy of the product.

Previous Page

Next Page

Previous Page

Next Page