Self-diagnosis technology for gas mass flow controllers

Publish Time:

2020-03-26 17:32

Source:

1. Self-diagnosis Technology

Self-diagnosis technology involves determining the normal status of equipment, the cause, location, extent of abnormalities or failures, and predicting its lifespan, through various detection and analysis methods without downtime or significant disassembly.

The main function of self-diagnosis technology is to obtain the resulting status information of the equipment, which means identifying the product's status, abnormality type, and severity based on a comprehensive analysis of all status information, such as out-of-tolerance accuracy, zero-point drift, internal leakage, etc., exhibited by the equipment under various operating conditions. Its essence is a process that includes signal acquisition, information extraction, information synthesis, fault identification, and information utilization. The goal of self-diagnosis is to ensure stable operation of the product in terms of functionality, accuracy, efficiency, and reliability.

Figure 1 Goals of Self-diagnosis

2. Application of Self-diagnosis Technology in Gas Mass Flow Controllers

The most important requirement for gas mass flow controllers in semiconductor equipment is high accuracy. Traditional gas mass flow controllers, after a period of use, may experience accuracy deviations due to factors such as ambient temperature and gas contamination. However, due to detection limitations, users cannot verify the accuracy of these controllers. Therefore, there is a need to research a self-diagnosis technology that allows users to check the accuracy of gas mass flow controllers at any time.

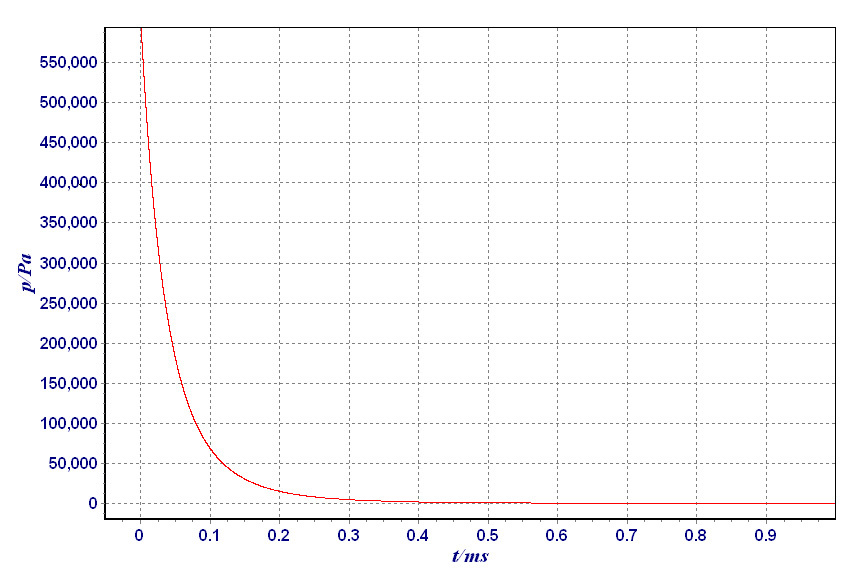

To add a self-diagnosis function to gas mass flow controllers, flow needs to be obtained through a primary flow measurement principle. If Qm is the mass flow rate of the gas, a pressure change over time curve can be established based on pressure, temperature, and gas flow change equations, as shown in Figure 2:

Figure 2 Pressure Change Curve Over Time

Based on this figure, an accuracy correspondence table for the gas mass flow controller can be established. During the self-diagnosis process, by comparing with the information in this table, the system's accuracy can be determined to be within the required range based on the similarity of the two curves. Self-diagnosis technology significantly improves the reliability of gas mass flow control systems and enhances their functionality.

3. Advantages of Self-diagnosis Technology

By employing intelligent analysis with self-diagnosis technology, mass flow controllers can perform intelligent detection, predict potential failures of the equipment, and based on these predictions, automatically eliminate them or trigger alarms. This process yields better economic benefits for the maintenance of the product during use. Not only can the workload of staff be effectively reduced, but comprehensive self-diagnosis results can also be provided, allowing maintenance personnel to formulate more complete and effective maintenance plans, making the implementation of repairs and maintenance more logical.

Previous Page

Next Page

Previous Page

Next Page